Stormwater Management: Five Reasons to use a StormTank Module Over an Arch Product

In today’s stormwater market, there are two main product types used to manage runoff in subsurface applications: box systems and arch-shaped products. Both are designed to accomplish the same function: create a void space for stormwater and support the surface above. So, which product is better?

Here are the top five things you should assess against your project needs:

Overall Footprint

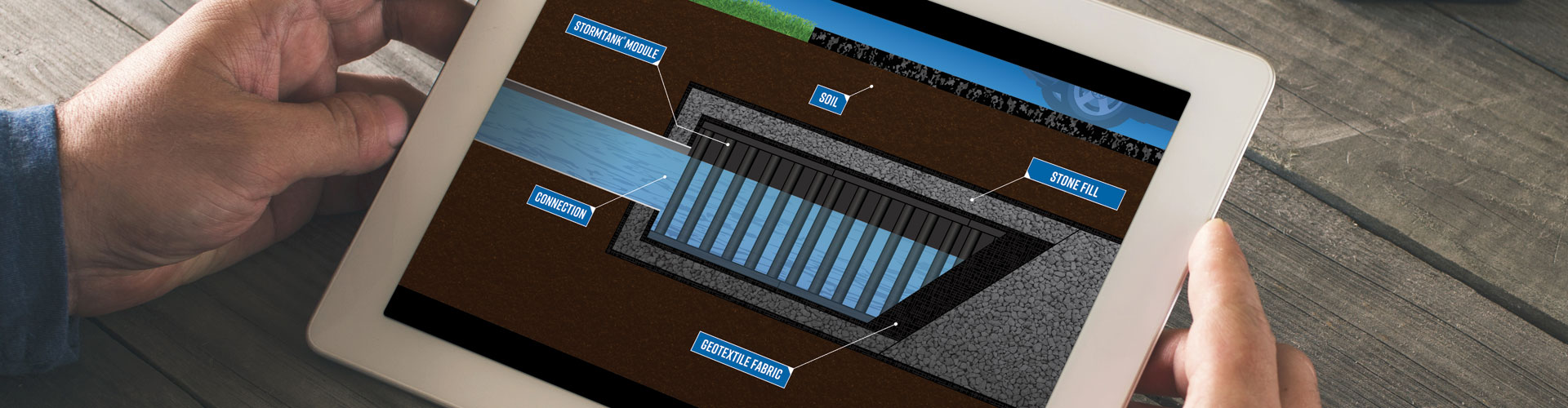

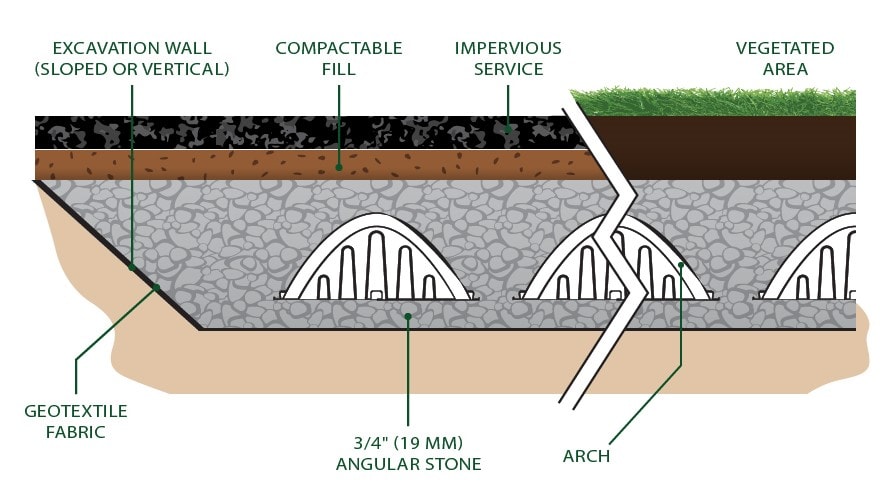

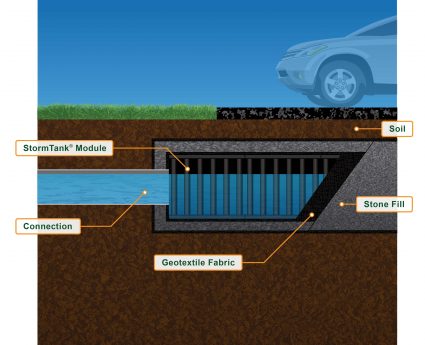

Arches require a much larger footprint than box systems, which is tied to the amount of excavation and backfill material the contractor will have to haul and place. On average, a StormTank Module can reduce the stone backfill by 40-60%. Depending on the region, this can translate to huge cost savings. For example, most installations require hundreds and thousands of tons of stone, which is typically anywhere from $40-50 per ton.

Box structures can also be flexibly designed to meet specific site requirements and layouts. The Module 25 Series is easily designed around existing structures and within tight constraints, offered in a range of heights to vary storage capacity, and is stackable to reduce installation footprint.

Capacity

Since box structures feature a higher void space than arches, they rely less on the stone backfill for storage capacity. For this reason, box systems with less height can accomplish the same capacity as a deeper arch. This means the excavation depth can be reduced, less rocks will need to be removed, and the box units can be placed above the water table.

Buoyancy

Buoyancy

All underground storage systems are susceptible to buoyancy issues depending on the submergence depth. However, arch systems are more at risk of reduced capacity or damage caused by buoyancy because there is no restraint under the arch itself. This means the liner and stone leveling bed can rise into the void space and reduce storage capacity when surrounded by groundwater.

Ease of Installation

Though box structures require some level of field assembly, they can be moved and placed by a single individual. In fact, StormTank Modules can be assembled in less than two minutes, and our Module 20 Series is able to be assembled in under 90 seconds, and are easy to place and connect. On the other hand, arch products typically require multiple people to move and place the product, technically doubling the time to install one unit, with some taller sizes even requiring a third person. Additionally, because each arch system is made up of multiple product rows, the system requires a manifold that box structures do not.

Strength

This point is commonly misunderstood and can vary as much by a manufacturer as by product type. If we use the StormTank Module 25 Series as an example, it has been designed and tested to support the load above it better than most arch products. However, the only true way to determine a strength comparison is to conduct full-scale installation testing, utilizing tools like strain and displacement gauges. (Do not be fooled by steel press tests that don’t gather meaningful data or driving uncalibrated trucks over the system!)

The bottom line: Arches can be a cost-effective means for managing stormwater if the system is simple in configuration, does not require an impermeable liner, and stone is cheap in the region. Far more often, box structures are competitive or even less expensive than arches but can be overpriced by contractors who are not familiar with them; this unfamiliarity leads them to believe that assembly time will be much greater in terms of time and cost, but in most cases, the stone savings alone will more than offset the labor cost differential.

To learn more about Brentwood’s StormTank products, please visit our website. If you’re interested in contacting us to discuss a project, please submit a contact form or give us a call at 610-374-5109.