A Guide to StormTank® Module Inspection and Maintenance

Stormwater detention systems, like the StormTank Module 25 Series, are critical infrastructure for controlling runoff and preventing flooding and pollution. But to function as designed, these systems must be properly maintained and regularly inspected. This guide to StormTank Module inspection and maintenance will walk through recommended inspection intervals and maintenance best practices to extend the life and performance of your Module system.

Why Inspection and Maintenance Matter

Subsurface stormwater storage systems rely on unobstructed flow and clean chambers to effectively manage stormwater. Over time, sediment, debris, and seasonal materials (like leaves or salt) can accumulate and compromise flow or block outlets, potentially leading to backups or flooding. Preventive maintenance and routine inspections ensure:

• Proper system performance

• Long-term durability of components

• Compliance with Best Management Practices (BMPs) and regulatory requirements

• Avoidance of costly repairs or replacements

Maintenance Procedures

Regular inspection and cleaning are essential to maintaining maximum performance and hydraulic capacity of your detention system. The following procedures outline general guidance for identifying debris accumulation, documenting system conditions, and restoring proper operation when maintenance is required.

Inspection:

a. Inspect all observation ports, inflow and outflow connections, and the discharge area.

b. Identify and log any sediment and debris accumulation, system backup, or discharge rate changes.

c. If there is a sufficient need for cleanout, contact a local cleaning company for assistance.

Cleaning:

a. If a pretreatment device is installed, follow manufacturer recommendations.

b. If using a vacuum pump truck, evacuate debris from the inflow and outflow points.

c. Flush the system with clean water, forcing debris from the system.

d. Repeat steps b and c until no debris is evident.

Inspection Best Practices

Year 1: Establishing a Baseline

The first year is the most important for understanding your site-specific sediment and debris patterns. During this period, systems should be inspected more frequently to establish a baseline and set a long-term maintenance plan. Visual inspections should be completed during and after each major rainfall event, in addition to semi-annual inspections.

Several factors influence site-specific inspection and maintenance needs, including:

• System design, such as whether inlet protection or a pretreatment device is included

• Runoff sources, including hardscape, gravel, landscaped areas, or exposed soil

• Seasonal conditions, such as leaves in the fall and sand application during winter

Systems that lack pretreatment or receive runoff from high-sediment areas typically require more frequent inspections and cleaning.

Year 2 and Beyond: Routine Maintenance

After the first year, your team should have a reliable understanding of the system’s behavior. From this point forward, conduct inspections semi-annually at a minimum. Consider additional inspections with seasonal changes (fall leaves, cinders, salt, sand, etc.).

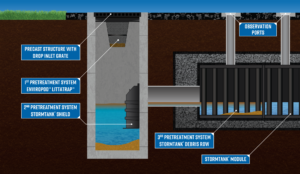

Pretreatment Devices for Sediment and Debris Control

Incorporating pretreatment can help address many of the maintenance challenges identified during routine inspections. Pretreatment devices help control sediment, trash, and debris at the point of entry. By capturing pollutants early, pretreatment can extend system life and support more consistent inspection and cleaning schedules.

We offer several pretreatment options to address varying site conditions and debris loads:

• EnviroPod™ LittaTrap™ – A catch basin insert designed to capture trash, floatables, and organic debris.

• Hydroworks HydroDome – A hydrodynamic separator used to remove TSS, debris, and trash from stormwater.

• StormTank Shield – An inlet-based pretreatment device that intercepts sediment and debris before it enters the stormwater system.

• StormTank Debris Row – A modular row within StormTank Module systems that isolates coarse sediment and debris for easier access.

These solutions can be used in tandem to create a comprehensive pretreatment strategy that captures debris at multiple points, improving overall system performance and reducing downstream maintenance.

Supporting Long-Term System Performance

A properly maintained StormTank Module system is a reliable and efficient tool for stormwater management. Investing time in inspections and cleaning will pay dividends in performance and lifespan. Be sure to log all maintenance activities and adjust inspection frequency based on your site’s specific needs.

With proper planning and regular care, your Module system will deliver long-term results, working below the surface to protect your site, infrastructure, and environment for decades to come.